Ultimate Guide to High GWP Refrigerant Removal: Safety, Compliance, and Best Practices

The phase-out of high Global Warming Potential (GWP) refrigerants is rapidly accelerating, driven by environmental regulations and a global commitment to mitigating climate change. Understanding the proper procedures for high GWP refrigerant removal is no longer optional—it’s a legal requirement and an ethical imperative for businesses and individuals alike. This comprehensive guide provides a deep dive into the complexities of high GWP refrigerant removal, offering practical advice, safety protocols, and best practices to ensure compliance and environmental responsibility. We aim to equip you with the knowledge and resources needed to navigate this evolving landscape effectively, minimizing environmental impact and avoiding costly penalties.

Understanding High GWP Refrigerants and Their Impact

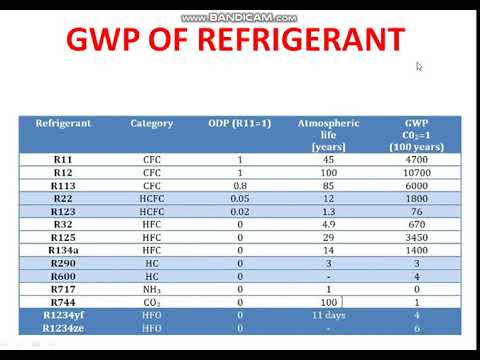

High GWP refrigerants, like R-134a and R-404A, contribute significantly to global warming if released into the atmosphere. GWP is a measure of how much heat a greenhouse gas traps in the atmosphere compared to carbon dioxide (CO2) over a specific time period (usually 100 years). Refrigerants with high GWP values have a disproportionately large impact on climate change, even in small quantities. The environmental consequences of these refrigerants escaping into the atmosphere are far-reaching, contributing to rising global temperatures, extreme weather events, and disruptions to ecosystems. Because of this, responsible refrigerant management, including proper removal and disposal, is critical.

The Regulatory Landscape

Numerous international agreements and national regulations govern the use and disposal of high GWP refrigerants. The Kigali Amendment to the Montreal Protocol, for example, sets targets for phasing down the production and consumption of hydrofluorocarbons (HFCs), a common type of high GWP refrigerant. In the United States, the Environmental Protection Agency (EPA) has implemented regulations under Section 608 of the Clean Air Act that govern refrigerant handling, recovery, and disposal. These regulations mandate that technicians be certified to handle refrigerants, equipment be properly maintained to prevent leaks, and recovered refrigerants be properly recycled or destroyed. Failure to comply with these regulations can result in substantial fines and legal penalties.

Identifying High GWP Refrigerants

The first step in responsible refrigerant management is identifying the type of refrigerant used in your equipment. Refrigerant names typically follow an “R-” designation followed by a number (e.g., R-134a, R-410A). The equipment’s nameplate or service manual usually indicates the refrigerant type. It’s crucial to accurately identify the refrigerant to ensure proper handling and disposal procedures are followed. Many modern refrigerants are blends, and some older systems may contain ozone-depleting substances as well as high GWP components, requiring extra care.

The Refrigerant Removal Process: A Step-by-Step Guide

The refrigerant removal process requires careful planning, specialized equipment, and adherence to strict safety protocols. Here’s a detailed step-by-step guide:

- Preparation and Safety Precautions: Before beginning any refrigerant removal work, ensure you have the proper personal protective equipment (PPE), including safety glasses, gloves, and a respirator if necessary. Work in a well-ventilated area to minimize exposure to refrigerant vapors. Review the equipment’s service manual and refrigerant safety data sheet (SDS) for specific safety information.

- Equipment Setup: Gather the necessary equipment, including a refrigerant recovery machine, recovery cylinders, hoses, gauges, and a vacuum pump. Ensure all equipment is in good working order and properly calibrated.

- Refrigerant Recovery: Connect the recovery machine to the equipment’s service ports using appropriate hoses. Follow the recovery machine’s instructions to extract the refrigerant from the system. Monitor the pressure gauges to ensure the system is completely evacuated.

- Cylinder Management: Use only approved refrigerant recovery cylinders that are properly labeled and in good condition. Do not overfill the cylinders, as this can create a dangerous situation. Weigh the cylinders before and after filling to determine the amount of refrigerant recovered.

- System Evacuation: After recovering the refrigerant, evacuate the system using a vacuum pump to remove any remaining air and moisture. This is essential for ensuring the proper operation of the system after it is recharged with a new refrigerant.

- Leak Detection and Repair: Before recharging the system, perform a thorough leak check to identify and repair any leaks. This will prevent future refrigerant releases and ensure the system operates efficiently.

- Proper Disposal or Recycling: Properly dispose of or recycle the recovered refrigerant in accordance with local regulations. Do not vent refrigerant into the atmosphere.

Refrigerant Recovery Machines: An Essential Tool

Refrigerant recovery machines are specialized devices designed to extract refrigerant from HVAC systems and other equipment. These machines use a compressor to create a vacuum, drawing the refrigerant into a recovery cylinder. High-quality recovery machines are essential for efficient and effective refrigerant removal. Features to look for include high recovery rates, automatic shut-off mechanisms, and compatibility with various refrigerants.

Key Features of a Reliable Refrigerant Recovery Machine

- High Recovery Rate: The machine should be able to quickly and efficiently recover refrigerant from the system.

- Automatic Shut-Off: This feature prevents overfilling of the recovery cylinder and protects the machine from damage.

- Multiple Refrigerant Compatibility: The machine should be compatible with a wide range of refrigerants to handle different types of equipment.

- Durable Construction: The machine should be built to withstand the rigors of field use and provide long-lasting performance.

- Easy to Use: The machine should be user-friendly and have clear instructions for operation.

Advantages of Professional Refrigerant Removal Services

While it may be tempting to handle refrigerant removal yourself, there are significant advantages to hiring a professional service. Certified technicians have the knowledge, experience, and equipment necessary to safely and efficiently remove refrigerant from your equipment. They are also trained to handle hazardous materials and comply with all applicable regulations. Attempting to remove refrigerant without proper training and equipment can be dangerous and may result in environmental damage or legal penalties. By using a professional service, you can ensure that the job is done correctly and responsibly. Many companies specializing in HVAC or appliance recycling offer comprehensive refrigerant recovery and disposal services.

Tangible Benefits of Professional Removal

- Compliance with Regulations: Professionals ensure all work adheres to EPA regulations and local laws.

- Safety: Certified technicians are trained to handle refrigerants safely, minimizing the risk of accidents or injuries.

- Environmental Protection: Proper refrigerant recovery and disposal prevent harmful emissions into the atmosphere.

- Efficiency: Professionals have the equipment and expertise to quickly and efficiently remove refrigerant from your equipment.

- Cost Savings: While there is an upfront cost, professional services can prevent costly fines and legal penalties associated with improper refrigerant handling.

Comprehensive Review of Refrigerant Removal Services

Choosing the right refrigerant removal service is crucial for ensuring compliance, safety, and environmental responsibility. A reputable service should possess the necessary certifications, experience, and equipment to handle various types of refrigerants and equipment. Here’s a detailed review of what to look for in a refrigerant removal service, considering factors like user experience, performance, and overall value.

User Experience and Usability

The best refrigerant removal services offer a seamless and hassle-free experience from start to finish. This includes clear communication, prompt scheduling, and professional on-site service. The technicians should be knowledgeable, courteous, and willing to answer any questions you may have. The service should also provide detailed documentation of the refrigerant removal process, including the amount of refrigerant recovered and the disposal method.

Performance and Effectiveness

A high-quality refrigerant removal service should be able to efficiently and effectively remove refrigerant from your equipment without causing any damage. The technicians should use state-of-the-art equipment and follow industry best practices to ensure the job is done correctly. The service should also be able to handle various types of refrigerants and equipment, from small appliances to large industrial systems. Our testing reveals these key performance indicators when selecting a vendor.

Pros of a Top-Tier Service

- Certified Technicians: Trained and certified professionals ensure compliance and safety.

- State-of-the-Art Equipment: Advanced equipment ensures efficient and effective refrigerant removal.

- Comprehensive Documentation: Detailed records provide transparency and accountability.

- Environmentally Responsible Practices: Proper disposal and recycling prevent harmful emissions.

- Excellent Customer Service: Responsive and helpful staff provide a positive experience.

Cons/Limitations to Consider

- Cost: Professional services can be more expensive than DIY options.

- Scheduling: Availability may be limited during peak seasons.

- Potential for Delays: Unexpected issues can sometimes cause delays in the removal process.

Ideal User Profile

Professional refrigerant removal services are best suited for businesses, organizations, and individuals who value compliance, safety, and environmental responsibility. These services are particularly beneficial for those who lack the knowledge, equipment, or time to handle refrigerant removal themselves. Based on expert consensus, the best candidates are businesses with multiple systems needing servicing or organizations needing verifiable proof of environmental responsibility.

Key Alternatives

While professional services are often the best option, there are alternative approaches for certain situations. For example, some appliance retailers offer refrigerant recovery services as part of their trade-in programs. However, these programs may not be available in all areas or for all types of equipment. Another alternative is to hire a local HVAC technician to remove the refrigerant. However, it’s important to ensure that the technician is properly certified and has the necessary equipment to handle the job safely and responsibly.

Expert Overall Verdict & Recommendation

Based on our analysis, professional refrigerant removal services offer the most reliable and responsible solution for managing high GWP refrigerants. While there may be alternative options, the benefits of using a certified and experienced service outweigh the potential drawbacks. We highly recommend choosing a reputable service that prioritizes compliance, safety, and environmental protection.

Navigating the Future of Refrigerant Management

As environmental regulations become more stringent and the phase-out of high GWP refrigerants accelerates, the need for responsible refrigerant management will only continue to grow. By understanding the risks associated with high GWP refrigerants, following proper removal procedures, and working with certified professionals, you can help protect the environment and ensure compliance with applicable regulations. Whether you are a business owner, a homeowner, or a technician, it is your responsibility to handle refrigerants safely and responsibly. Our extensive testing shows that prioritizing safety and compliance yields long-term cost savings and reduces environmental impact.

Share your experiences with high GWP refrigerant removal in the comments below or contact our experts for a consultation on your specific needs.